After years of unremitting efforts and profound development, RENK's products have been deeply integrated into the development of wind power generation. Whether it is the related components of the wind turbine transmission chain, the core components of the wind turbine transmission chain or the testing of the whole machine, RENK's products and services have won widespread praise and high recognition from customers in the wind power field.

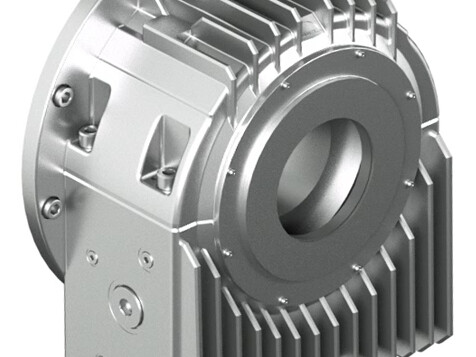

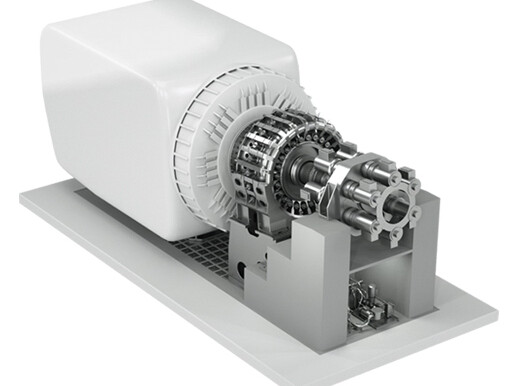

Wind Turbine Spares | Slide Bearings

Main Slide Bearings & Main Shaft Slide Bearings

- Inovative and integrated slide bearing design

- Fully scalable to load requirements and turbine size

- Wear-free, hydrodynamic operation over full turbine lifetime

Planetary pin slide bearings

- Designed and validated specifically for planetary stage bearings

- Coating directly on planet carrier pin with exceptional material bonding strength

- Sliding material with excellent wear resistance

- Delivered final machined for direct assembly in gearbox

Generator shaft slide bearings

- Slide bearings for the upcoming generator evolution

- Advanced especially for large generator shaft sizes

- Wear-free, hydrodynamic operation over full turbine lifetime

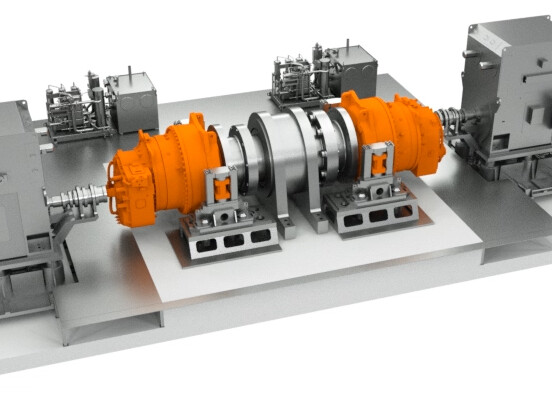

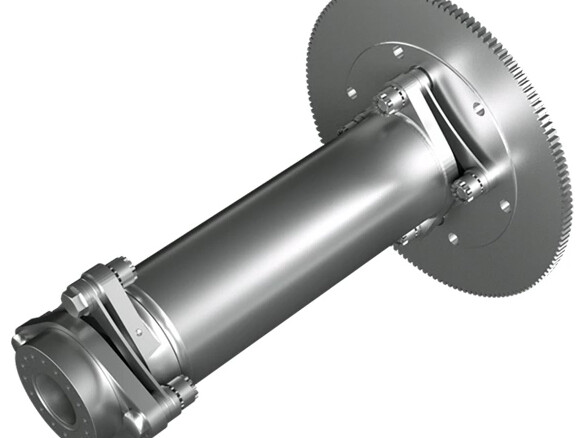

Wind Turbine Spares | Couplings

EQ-Flex with InnovativeTorque Limiting Unit

- Ensures an adjustable and constant slip torque during operation

- Countinuous torque measurement

- Slipping process is recorded and evaluatedby the RENK Condition Monitoring System

- Simple torque adjustment without disassembly of coupling.

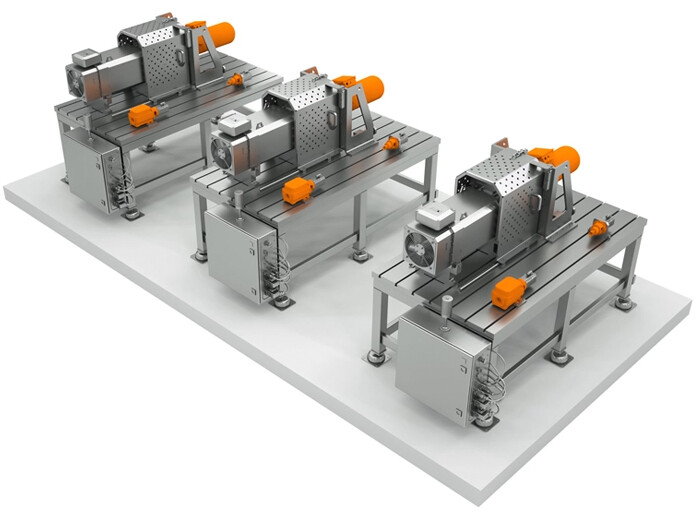

Wind Turbine | Test Rigs

Pitch Drive Test Rigs

- Testing of individual components or up to 3 pitch drives in interaction

- HIL- and SIL-Testing with open external model integration

- Compatible for AC- and DC-Motors

- Emergency shutdown tests with dynamic turbine grid simulation

Pitch Bearing Test Rigs

- Bearing tests in real installation situation

- Measurement of bearing efficiency possible because of interference-free test bench design

- Load compensation to minimize the foundation load

Main Bearing Test Rigs & Main Shaft Bearings Test Rigs

- Testing of single main bearings or complete mainshaft bearing assemblies

- 5 DOF Load application unit up to 113 million Nm bending moment

- Load application unit based on pioneering slide bearing technology

- Unique multi-axis measuring flange

- Highly dynamic load application and maximum measuring accuracy

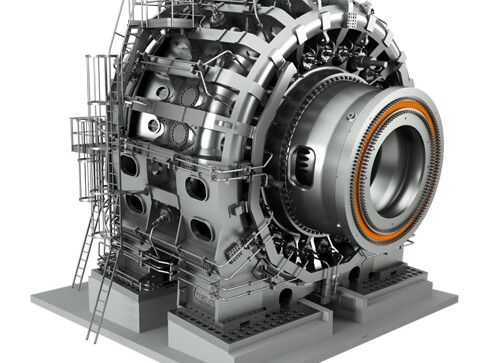

Gearbox Test Rigs

- Testing of different gearbox and drivetrain designs

- Specimen support and main shaft interface according to real installation situation

- Measurement of gearbox efficiency possible because of interference-free test bench design

- Simple and quick change of test piece

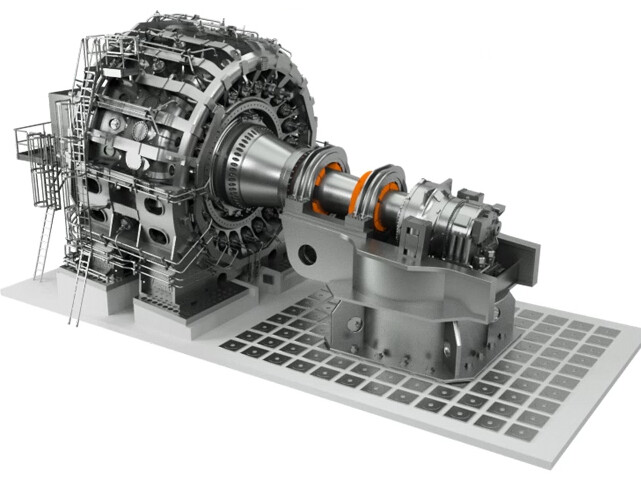

Nacelle Test Rigs Drivetrain Test Rigs

- Scalable multi-motor drive with a maximum torque of 47 million Nm

- 5 DOF Load application unit up to 113 million Nm bending moment

- Integrated grid simulator with power feedback

- Top level test rig automation system

- Integration of the wind turbine control (HlL and SIL testing of the overall system)

Contact us

Feel free to explore our website for any inquiries regarding our company. Should you have any questions or requirements concerning our services, please don't hesitate to reach out to us.

We are happy to assist you!